The typical value for Youngs Modulus varies from 10000000 to 10600000 depending on alloy with the higher strength alloys. As Intial length I Is constant value of DI can become less only when D is less.

Young S Modulus Versus Temperature For Aa2618 In T6 State And For Three Download Scientific Diagram

Steel which is a metal alloy iron containing up to 214 carbon and the Youngs Modulus of steel is taken as 210 GPa or 205 GPa whereas a Nylon polymer has a Youngs.

Young's modulus aluminium vs steel. The change in Youngs Modulus with temperature was included in the material properties for both the wedges Equation 3 37 and the aluminium Equation 4 38 using piecewise functions. IFRs Petroleum 31 Aug 05 0737. ASTM A36 Carbon Steel.

For discussion lets simplify the problem by considering one 15 x 15 tube as a simply loaded column. 49 rows Modulus of Elasticity Average Properties of Structural Materials Shear Modulus Poissons. Youngs modulus can be used to predict the elongation or compression of an object.

Substituting the value of ΔZ in equation 2. Tensile Modulus - or Youngs Modulus alt. All materials are plastic to some extent but the degree varies for example both mild steel and rubber are elastic materials but steel is more elastic than rubber.

Please note that the two materials have. Professor Rankine has suggested that we combine the load requires to crush the column with Eulers buckling load to obtain the load that the column can withstand. 52 rows The Youngs modulus of steel also referred to as modulus of elasticity of steel.

Its value is about one third that of steel but contrary to density this is a disadvantage compared to steel. Steel is more elastic than rubber. Steel however is the strongest whereas aluminum is the lightest.

Modulus of Elasticity for some common metals at various temperatures according ASME B311-1995. Youngs modulus has been determined for aluminium copper iron brass and certain steel alloys by using DEHI technique. 7075-T6 aluminum belongs to the aluminum alloys classification while ASTM A36 carbon steel belongs to the iron alloys.

Youngs modulus of elasticity for aluminum is 69 GPa or 69 x 109 Pascals. Strain comes less only when DI is less. It means value of strain for aluminium is much less than steel.

It is used to describe the elastic properties of objects like wires rods or columns when they are stretched or compressed. Cost and price are always an essential factor to consider when making any product. Brass on the other hand is the most conductive of these three metals.

Modulus of elasticity or also referred to as Youngs modulus is the ratio of stress to strain in elastic range of deformation. To C 59To F - 32 For full table with Higher Temperatures - rotate the screen. Aluminum seems obvious because it is lighter than steel but steel is stronger than aluminum so one could imagine using thinner steel components to save weight without sacrificing tensile strength.

The material properties are expressed in average values or in ranges that can vary significantly depending on the processing and of. However steel is generally cheaper per pound than aluminum see galvanized vs stainless for more info on steel. The price of steel and aluminum is continually fluctuating based on global supply and demand fuel costs and the price and availability of iron and bauxite ore.

The Young modulus is important for the structural behaviour. There are 31 material properties with values for both materials. Youngs modulus of aluminium is around 3 times more than steel.

1 psi lbin 2 1 psi lbin 2 144 psf lb f ft 2 68948 Pa Nm 2 6895x10-3 Nmm 2. Per The Aluminum Association the typical Youngs Modulus for the 70xx alloys is 10400000 psi and does not change based on the temper or heat treatment. We know the elastic modulus of steel is about 25 times that of aluminum.

7075-T6 Aluminum vs. Modulus of elasticity is also a measure of materials stiffness or resistance to elastic deformation. Properties with values for just one material 1 in this case are not shown.

Find the new length of the bar. Modulus of Elasticity - is a measure of stiffness of an elastic material. Tensile Modulus is defined as the.

Steel aluminum and brass sheet metal are all relatively strong and offer a high level of protection against corrosion. Then the value of Youngs modulus can be calculated from Y WL 3 Cos θ i Cos θ o 3 I Nλ5 Experimental Results of Y for metals and alloys. The tables below show the values of Youngs modulus modulus of elasticity and Poissons ratio at room temperature for several nonferrous metals used in engineering.

Ratio of stress force per unit area along an axis to strain ratio of. The low value of the Young modulus has a big influence on the deformations of an aluminum structure. For typical metals modulus of elasticity is in the range between 45 GPa 65 x 10 6 psi to 407 GPa 59 x 10 6 psi.

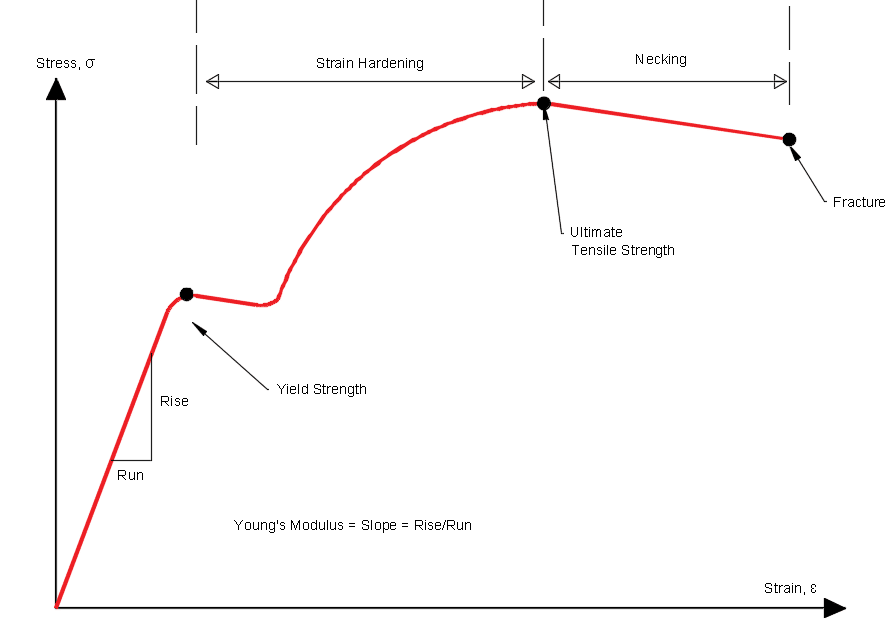

A stress of 23 GPa is applied to an aluminum bar of length 5 m. Modulus of elasticity or Youngs modulus is the slope of the stress-strain curve in the elastic region. Hopefully this gives you a better idea of the three different types of sheet metal.

Metal alloys and elements have strong interatomic bonds between the atoms resulting in high values of Youngs modulus whereas polymers have weak intermolecular bonds leading to smaller values of Youngs Modulus. Aluminum vs Steel Cost. 28 rows Modulus of Rupture.

Solved Young S Modulus Of 1060 Cr Chegg Com

Young S Modulus Of The Aluminum Graphite Particulate Mmc Download Scientific Diagram

Do Metals Generally Have Larger Values Of Young S Modulus Than Alloys If Yes Then Is Steel An Exception Physics Stack Exchange

Elastic Modulus Ahss Guidelines

Do Any Steel Alloys Have Significantly Different Young S Modulus Compared To Other Steel Alloys Quora